A recirculation chiller is laboratory equipment that is a high-efficiency closed cooling system used in various external cooling applications. These devices are especially ideal for laboratory applications that require continuous use.

These equipment provide a consistent and reliable source of liquid refrigerant for refrigeration in laboratory, clinical or industrial applications. A recirculating chiller can reach temperature ranges from -25 °C to 130 °C (therefore some may act as heaters as well). Digital PID temperature controllers ensure that the recirculation cooler reaches the desired temperature accurately and quickly.

What is the function of a recirculation cooler?

The primary function of a recirculation cooler is to remove mechanical or electrical heat operating under the principle that the temperature of an object or system is controlled by the flow of heat in or out. They are commonly used to provide constant low temperature conditions for inspections, chemical, biological and physical experiments to be carried out at low temperature, mainly employed in the field of medicine, food processes, chemical industry and teaching in universities and research institutes.

Among the main common characteristics of recirculation chillers are:

- Closed circulation system can prevent cooling

- medium evaporation and pollution, save energy.

- The circulation system is equipped with a filter, which keeps the cooling medium clean and prevents instrument clogging.

- They have a built-in liquid level monitor, liquid level inside

- the bathroom can be checked visually.

- The circulation system is equipped with gage, it shows the pressure of the circulation system.

- Most recirculation chillers as mentioned above can operate at temperatures between -25 ºC to 130 ºC.

How does a recirculation cooler work?

A recirculation chiller works by incorporating high-pressure flow refrigerant circulation to accelerate the process of removing heat from an object. These systems consist of: a compressor, a condenser, a thermostatic expansion valve and an evaporator. And the cooling process starts when you pump the refrigerant gas into the compressor and it becomes a gas at high temperature and pressure. This gas then travels to the condenser where air or ambient water takes heat from the refrigerant and condenses it from gas to liquid.

Later in its liquid state, the coolant passes through the thermostatic expansion valve where pressure and temperature decrease, causing the fluid to evaporate and turn into gas. When the gas condition returns, the refrigerant is returned to the compressor and the process begins again. Because it is a continuous service, recirculation chillers do not waste any refrigerant or water during the entire process. It is important to note that this process may vary slightly depending on whether the recirculation chiller has a water or air cooled condenser.

What does Kalstein offer you?

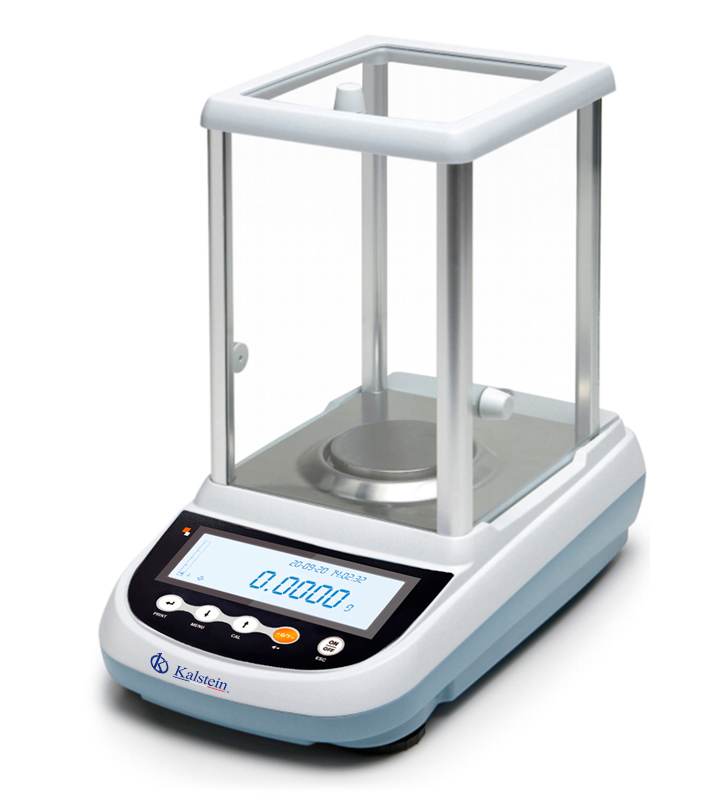

Kalstein is a manufacturer of medical and laboratory equipment of the highest quality and the best technology at the best PRICES in the market, so you can make your PURCHASE confidently with us, knowing that you have the service and advice of a company specialized in the field and committed to provide you with safe, economical and effective options to perform your functions in the right way.

This time we present our Recirculation Cooler YR02293 – YR02296. This innovative equipment with cutting edge technology has the following features:

- Applications in chemistry and biology, such as biological fermenter and synthetic chemical vessel.

- Equipped with world famous brand compressor, it guarantees low noise level, high reliability, stable performance and long service life.

- The fully enclosed circulation system prevents bath fluid from evaporating or becoming contaminated.

- The filters incorporated in the circulation hose prevent possible obstructions.

- The environmentally friendly CFC-free refrigerant meets international standards.

- Compact design with attractive appearance

- Designed with liquid level monitor, which facilitates the verification of the remaining bath liquid in the tank.

- The pressure of the bath fluid can be measured with the pressure gage that is fixed near the outlet of the fluid.

- Variable models to meet different customer requirements.

- Removable side panels for quick and easy cleaning and maintenance.

- The eco-friendly refrigerant meets the international environmental protection standard; The intelligent control system will prevent the compressor from overloading, which will prolong its service life; closed circulation system that reduces refrigerant evaporation.

For more information we invite you to take a look HERE