Ovens

It is used to sterilize or dry glass and metal material used in examinations or tests, which is converted to the laboratory and comes from the washing section, where it is sent after being used in a procedure. Sterilization carried out in the oven is called dry heat and is carried out at 180 ° C for 2 hours; Glassware, when heated by high temperature air, absorbs moisture and eliminates the possibility of maintaining any biological activity due to high temperatures and times used.

Quality control on stoves is a bit difficult to achieve because the dry heat sterilization technique has the critical temperature and time setting. In general, the spores of Bacillus Subtilis, the Niger variety, which must be incubated for several hours after the use of the sterilization process as biological indicators. The initial spore load of the biological indicator varies between 5 x 105 and 1 x 106. Its effectiveness depends on the diffusion of heat, the amount of heat available and the loss of heat. The action of the microbicide is conditioned by the presence of organic matter or dirt in the article. Dry heat sterilization should be limited to materials that cannot be autoclaved.

Types of Laboratory ovens a Laboratory May Need

Vacuum Ovens

- Vacuum environment greatly reduces the need to get rid of the liquid boiling point, so the vacuum

- Drying heat-sensitive material can be easily applied for is not easy to Drying the sample, such as powder or other granular samples using a vacuum Drying can effectively shorten the Drying time.

- Safety-under the conditions of vacuum and inertness, completely avoid exploding if oxidizing material in a very high temperature.

- Compare with the ordinary drying way depend on air circulating to drying, powder sample is not easy to be blew away by flowing air.

- Interior chamber use streamlines arc design, the outer is made of cold-rolled steel plate, the surface uses the electrostatic spray.

- Liner is made of stainless steel or cold rolled material, easy to clean because of corners semicircular.

Industrial Oven

- According to the box size single door or double door design. Large diameter centrifugal wind wheel. Uniform heat circulation.

- The shell is made of high quality cold-rolled steel with metallic paint spray. Nice overall color design. suitable for all workshop production.

- Digital display intelligent temperature controller with microcomputer intelligent PID control and timing function.

- Large diameter centrifugal wind wheel. uniform heat circulation.

- Two models material inner chamber: mirror stainless steel and zinc-plating.

- This series product with the feature of large storage and temperature rising is fast.

- YR05256 for the smaller product baking such as baked paint for toys hardware part.

In Kalstein you can find the Ideal ovens for your Laboratory

Double Door Industrial Air Drying Oven YR05257-1

Double layer door; Microcomputer intelligent temperature control, digital display; centrifugal wind wheel, heat ...

Single Door Industrial Air Drying Oven YR05256

Microcomputer intelligent temperature control, digital display; centrifugal wind wheel, heat flow evenly; large...

Electric heating drying oven YR05248

Lorem Ipsum es simplemente el texto de relleno de las imprentas y archivos de texto. Lorem Ipsum ha sido el texto...

Vacuum drying oven YR05260 (A) // YR05261

Vacuum drying oven widely used in biochemical, chemical, pharmaceutical, health care, agricultural research...

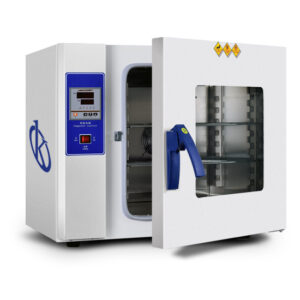

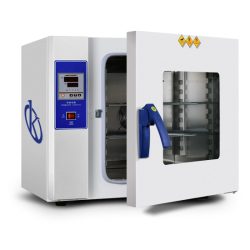

Our Best Selling ovens

Microcomputer intelligent PID control, precision LED display temperature control, timing, over-temperature alarm, RS 485 computer interface, mirror stainless steel inner, anti-acid, anti-corrosion; hot air circulation system and maintenance free. Widely used for drying, sterilization, thermostatic storage, heat treatment and other fields. Suitable for a higher temperature uniformity requirements user. The basis of laboratory research units supporting equipment, use recommended for intermediate and senior laboratory.

| Model | YR05244 | YR05245 | YR05246 | YR05247 |

| Temp range (℃) | RT+5~250 | |||

| Accuracy (℃) | ±0.1 | |||

| Fluctuation (%) | ±1 | |||

| Voltage (V) | 220 | |||

| Power (KW) | 1 | 1.2 | 1.6 | 2.5 |

| Inner size(mm)(H*W*D) | 320*350*350 | 420*450*350 | 520*550*450 | 750*600*500 |

| Overall dimension(mm)(H*W*D) | 530*640*550 | 630*740*550 | 750*890*630 | 980*965*770 |

| Packing size(mm)(H*W*D) | 650*720*630 | 750*820*630 | 870*970*710 | 1100*1045*850 |

| Net weight(KG) | 36 | 47 | 62 | 96 |

| Shiping weight(KG) | 39 | 50 | 66 | 105 |

Analysis of the best ovens for your Laboratory

Considerations to take into account when using a drying oven?

The drying oven is a device that is used to dry and sterilize glass and metal containers...

Laboratory ovens, which one to choose?

Among the wide variety of equipment needed to carry out the numerous activities of a laboratory, we can...

What is a laboratory stove for?

The laboratory stove is an instrument used to dry and sterilize glass containers, which come from a laboratory wash. In other words, this cavity chamber, which ...

Laboratory stoves: dry heat sterilization

Stoves, also known as drying stoves, are devices used to dry and sterilize glass and metal containers used in ...

Catalog of models of ovens on offer

-

Double Door Industrial Air Drying Oven YR05257-1 // YR05259-1

Select options This product has multiple variants. The options may be chosen on the product page -

Single Door Industrial Air Drying Oven YR05256 // YR05258

Select options This product has multiple variants. The options may be chosen on the product page -

Vacuum Drying Oven YR05265-1 (SS) // YR05995 (S)

Select options This product has multiple variants. The options may be chosen on the product page -

Vacuum drying oven YR05260 (A) // YR05261 (A) // YR05264 (A)

Select options This product has multiple variants. The options may be chosen on the product page

Guides to become an expert in ovens

How does a natural convection stove work?

A natural convection laboratory stove is one that extracts the air from the environment in which the stove is located...

Features and care of a Laboratory ovens? - Laboratory

The laboratory oven is a team used to dry and sterilize glass and metal containers. There are basically two types of stove: those that operate...

The drying oven: from the simple to the complex

The drying oven is a device used to dry and sterilize glass and metal containers in the laboratory. It is also identified with the name...

Types of Laboratory stoves

The laboratory stoves or drying oven is equipment used to dry and sterilize glass and metal containers in a laboratory. It is also known as a drying oven. They work between room temperature...

Frequently asked questions about Stoves from our customers

How to know the prices of ovens?

To know the price of the ovens we invite you to send us an email with your request through the contact form.

What are the delivery times of the ovens?

- If the equipment of your interest is in stock or if it must be manufactured.

- The type of freight you have chosen, this may be; air or sea.

How to make a purchase of ovens?

- By email: [email protected]

- By telephone: +33 (0) 1 78 95 87 02

- E-commerce: Via Kalstein's official website in your country.

How does the warranty work?

Can I request a quote online?

Of course, you can request a quote for the Kalstein team of your interest, directly from our official website. Once you have identified your preferred model, click HERE