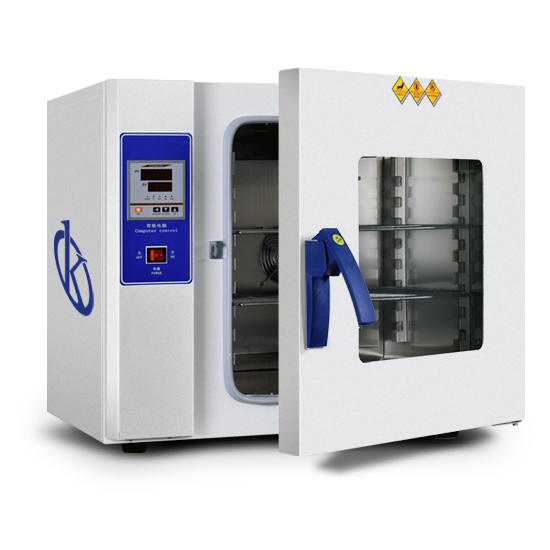

The drying oven is a device used to dry and sterilize glass and metal containers in the laboratory. It is also identified with the name Oven drying. The manufacturers have basically developed two types of ovens : those that operate by natural convection and those that operate by forced convection. The ovens operate, in general, between room temperature and 350 ° C

What is the purpose of the ovens ?

The drying oven is used to sterilize or dry the glass and metal material used in examinations or tests, carried out by the laboratory and that comes from the washing section, where it is sent after being used in some procedure. The sterilization that takes place in the ovens is called dry heat and is carried out at 180 ° C for 2 hours; The glassware, when heated by air at high temperature, absorbs moisture and eliminates the possibility of maintaining any biological activity due to the high temperatures and times used.

What services does this equipment require?

In order to be used, the drying oven requires the following:

- Have a work table of strong texture and well leveled.

- Condition around the ovens a free space of at least 5 cm and a space to place the material that must be processed in the equipment.

- Install an electrical outlet in good condition with properly dimensioned ground pole, to supply the electric power consumed by the ovens , which must comply with the national or international electrical regulations used by the laboratory and should not be more than 1 m from the team. The typical voltage used is 110 V or 220 V / 60 Hz.

- Verify that the electrical circuit has the required protection devices to ensure an adequate power supply.

What is required to operate it?

The operation of the ovens requires taking into account a series of precautions for its correct operation. Among the most important are the following:

- Do not use materials or substances that are flammable or explosive on the ovens .

- Avoid internal spills of acidic solutions or that form corrosive vapors, to avoid corrosion of interior surfaces and shelves.

- Use personal protection elements (insulated gloves, safety glasses and tweezers to place or remove substances or elements inside the drying oven)

How should your Quality Control be?

Quality control in the ovens is a bit difficult to perform, because the dry heat sterilization technique has temperature and time as critical parameters. In general, spores of Bacillus subtilis, Niger variety, are used as biological indicators and must be incubated several hours after the sterilization process. The initial spore load of the biological indicator ranges from 5 x 105 to 1 x 106. Its effectiveness depends on the diffusion of heat, the amount of heat available and the loss of heat. The microbicidal action is conditioned by the presence of organic matter or dirt in the article. Dry heat sterilization should be limited to materials that can not be sterilized in autoclaves.

Knowing that these equipments are one of the key elements of the laboratory, at Kalstein we offer you sophisticated drying ovens . That’s why we invite you to take a look at one of our models available HERE