The ideal tool for complex color analysis is by using color evaluation boxes, which determines the spectral illumination at each wavelength of any product, its accuracy is much greater and its range of applications is much wider.

Similarly, color evaluation boxes are necessary instruments for those professionals who support their research in the precision analysis of products, through the benefits that this tool brings, mainly in laboratories, for accurate color management of samples.

Therefore, these units have functionality mechanisms and operating systems that support the functions of these units, with important and specific features.

Functions of the Boxes

According to the needs of each user, the color evaluation boxes, ensures that the person who watches the product, has the same color capture, and even, under different lighting conditions. As an accessory, the light sources of a color assessment box include artificial daylight (D65), typical office, shop and exhibition lighting (TL84), household light (A) and UV component D65 defined according to D65. In addition, the colored boxes are a light source, with an additional UV source.

It is also important that the user is aware that the color assessment box is only necessary if he wants to check or make visible the artificial brighteners on the material, and the normal color checks do not require that the box includes an UV light source.

On the other hand, illumination is a fundamental factor in the functions performed by color evaluation boxes, and it is because the color of an object may appear different under different types of light. This variable often leads to inconsistencies between sample color and standard color. Because of this, it is necessary to standardize lighting conditions to maintain consistency.

- Maintain standardized light conditions by calculating samples within the controlled environment of a display box.

- Apply the same illumination source to the box, as the light source to be used where the object is shown.

- In order not to influence the appearance of the color of the sample, it is necessary to turn off all illumination at the site, if possible, except for the light source inside the evaluation box.

Identify Color Differences from an Evaluation Box

The description of an object, which equalizes color under the same light source or under a set of visual circumstances, but differs under other conditions, is what is known as metamerism. And through evaluations, visual and instrumental assessments are needed to calculate samples under two or more different light sources, such as daylight (Standard Illuminant D65) and incandescent light (Standard Illuminant A).

In this way, the steps to identify metamerism through a visual test are considered:

- Place samples in the evaluation box under a light source and compare visually.

- Change the light source (e.g. from Standard Illuminant D65 to Standard Illuminant A) and compare both samples to see if they match in color

- If the samples are assimilated under one light source but not under another, then they are considered to be a metameric pair.

For this reason, to confirm that the samples are metameric, an instrumental test must be fulfilled, using a spectrophotometer, since, e In cases where samples do not have the same exact color as the standard under all lighting conditions, it is important to identify metamerism and keep it to a minimum, in order to establish the appropriate color tools and processes.

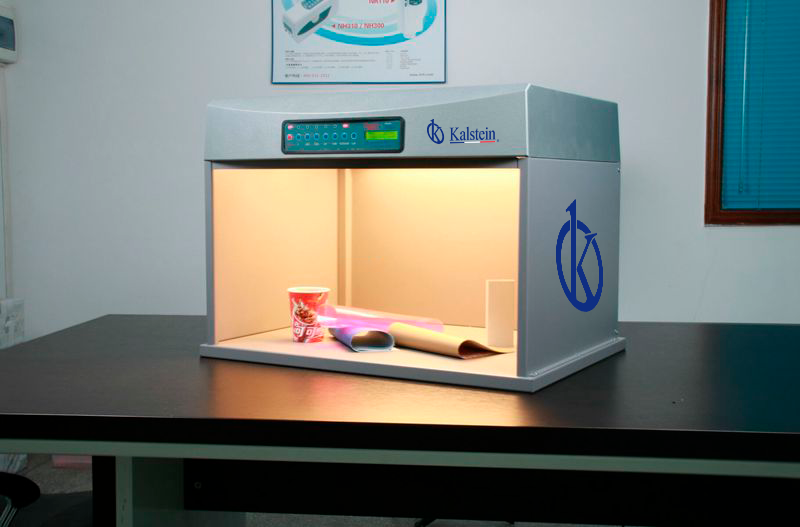

Kalstein Brand Color Evaluation Box

We at Kalstein are manufacturers of the best medical equipment and we are trained to offer you products of excellent quality, with the best advanced technology that our customers can enjoy. We have the Color Evaluation Boxes, of the YR model, which have general characteristics, such as: The LILO color light box reproduces the color more accurately. With 6 different light sources (D65, TL84, CWF, TL83/U30, F, UV). Meets or exceeds major international standards for visual color assessment including: ASTM D1729, ISO3664, DIN, ANSI and BSI. Easy to operate by using individual switches for each light source. Time elapsed meter to track optimal lamp replacement. Automatic switching between light sources.

For more information, check our catalog HERE We also offer the best advice, so that your purchase is ideal and at affordable prices.

Come visit us at: HERE