Recirculation chillers are highly efficient and safe equipment with energy saving capabilities for water condensation for various sectors. These equipment are designed to meet natural cooling processes using water as a coolant and transmit the right climate to the environment before thermal situations. Its operation is based on different mechanisms, using the condensation of refrigerating water for refrigeration installations for industrial, commercial refrigeration, air conditioning, heating, etc.

Its mechanism is based on the release of heat or cold, depending on the application with freedom of which are the specific particularities and characteristics, incorporating a series of changes of heat and wetted mass by means of water distribution mechanisms, ventilation method, intended to benefit the transfer of ambient air by means of change sections such as water container, recirculation pump, drop separators and control instruments.

In this sense, Kalstein has a variety of recirculation cooling equipment with attractive characteristics, providing the user to work with machines that suit their needs, thanks to its general characteristics, transmit reliability, since they are made with resistant materials, with various provisions and types of fans according to the specific requirements of each customer.

Benefits of Recirculation Coolers

Recirculation chillers are environmental control systems that benefit the food industry, mainly to ensure efficiency levels and energy savings to convert the appropriate and stable temperature in food manufacturing processes.

Recirculation chillers are present at all stages of the food production series, and use this type of equipment to remove condensed heat that originates from mechanical refrigeration facilities, i.e. those that originate and use artificial cold to spaces where food is conserved and transported.

In this sense, the management and conservation of fresh products, has to do with the conditioning of the cooling air that are carried out to achieve the appropriate conditions in the spaces where the products are processed, handled and packaged. The preservation of food is ensured by means of cold temperatures and appropriate for all processes, so that the product reaches the final consumer with the highest quality. This is the first reason justifying the use of recirculation chillers for the food industry.

Contributions of Recirculation Coolers

For the food sector, appropriate climate-controlled environments are necessary to ensure that the air retains a minimum amount of particulate matter and the products are not contaminated. The clean rooms achieve adequate and controlled environments thanks to the sterilization and sealing of the optimal temperature offered by the recirculation chillers, to meet the hygienic-sanitary requirements, so it is of great value to know what aspects to pay attention in the different white spaces where the processes of manufacture, preservation, storage and packaging of some type of food product are carried out.

To do this, the temperature of the water recirculation chillers must ensure that the operation is optimal and does not consume much energy, since the use of latent heat transmission evaporation, allows to eliminate the amounts of heat with the air flow as many times as necessary. Thanks to the technology they possess, condensation of environments reduces the risk of refrigerant leakage and direct impact.

Kalstein Brand Recirculation Coolers

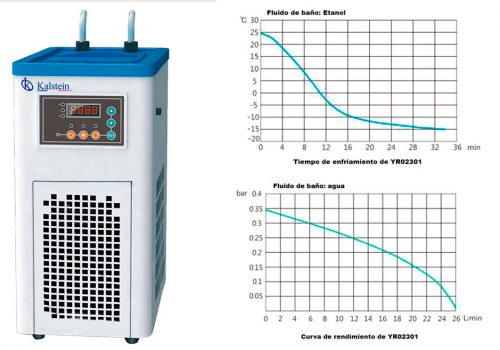

We at Kalstein offer you the best laboratory equipment, with the most advanced technology on the market. We have for our customers the Recirculation Cooler, belonging to the YR series, has water cooling processes to be used as refrigerant thanks to its safe and efficient technology, also has a nozzle circulating gasket that is rotated 360°, facilitating the complementary equipment.

Among many other features you can see from our catalog HERE We are manufacturers and we have the best advice, so that your purchase is the ideal and at excellent prices. To do this.